(727) 808-8602

| Home | Latest New Products | Customers' Rides | Orders, Terms and Conditions |

| What a crank-scraper is and other technical info... | Some comments on our products... |

|

(727) 808-8602

|

crankscraper, crank-scraper, crank-scrapper, oil wiper, crank, crankshaft, rod-bearing, main-bearing, connecting-rod, counterweight, piston, windage, windage-tray, windage-cloud, oil pan, oil-pan, oil-aeration, oil-foaming, oil-cloud, racing, drag racing, road racing, drag-race, road-race, road-course, drift, drifting, time-trial, performance, power, horsepower, HP, torque, TQ, friction, vacuum, economy, engine, motor

Copyright 2002-2026 © All rights are reserved on our product designs.

Ishihara-Johnson crank scrapers and other windage control products are a very simple but effective way to improve the performance of your motor!

What are some of the benefits?

· Less rotating mass for the engine to accelerate because of the removed oil

· Less loss of power because of excessive drag caused by oil droplets in the windage cloud

· Helps reduce engine damaging oil-foaming both on the surface and bubbles deeper within the oil

· Helps avoid oil starvation by keeping the oil in the pan during hard braking and turning as well as during off-road driving

· Helps to cool critical engine parts by quickly returning heated oil to the sump

· Helps to prevent the cylinder walls from being overloaded with oil

· Can help with fuel efficiency

During normal engine operation a significant amount of oil adheres to the rotating assembly or becomes entrained in a "windage" cloud surrounding it. It should be remembered that the particular characteristics of oil adhesion and/or oil-in-air entrainment vary depending on the engine rpm and what the vehicle is doing at the time. How the oil droplets are kept and drawn into the tornadic windage cloud is explained by the phenomenon known as the Tea Leaf Paradox, which was first described by Albert Einstein in 1926. It is counterintuitive that oil droplets would be kept and drawn into ("entrained") rather than completely expelled out of the windage cloud due to centrifugal force.

When a portion of the total droplets are small enough in physical size the predominate influence on their behavior switches. Rather than just their momentum due to being ejected from or impacted by the rotating assembly they are guided by the air currents in the windage cloud.* This droplet behavior in a gas atmosphere, which is a type of "fluid", in the confined volume of the crankcase is what the Tea Leaf Paradox addresses. The oil droplets have a greater density than the gas molecules.

Remember that an "equilibrium" of entrained oil is reached for the particular operating conditions. This means that not all the oil is held but rather that the amount rises until a certain point is reached and then the extra is not taken in or it swaps places with oil already in the cloud that is then released. Generally the higher the rpm, the more oil that is held because of the higher pressure differential. It is not unusual for a quart or more of oil to be suspended in the cloud at high rpms in many engines.

There are many alternate terms used for crank scrapers including -- but not limited to -- oil wipers, oil skimmers, and baffles.

* "High-speed video observation and phase Doppler anemometry measurements of oil break-up in a model engine crankcase" S. Begg, G. de Sercey, N. Miché and M. Heikal, Presented at ILASS - Europe 2010, 23rd Annual Conference on Liquid Atomization and Spray Systems, Brno, Czech Republic, September 2010. Full text available here: http://www.ilasseurope.org/ICLASS/ilass2010/FILES/FULL_PAPERS/097.pdf

This impacted and entrained oil eats up horsepower your engine is making by increasing the rotating mass and also creating parasitic drag. At low rpms and in extreme conditions where the rotating assembly is flooded by sump oil, the crank scraper mechanically strips off excess oil by coming close to, but not touching**, the moving crankshaft and rods. At high rpms it interferes with the pressure differential that draws oil into the windage cloud and allows a new lower equilibrium of entrained oil to be established.

Our crank scrapers are constructed from steel unless noted and include installation instructions. The scrapers are installed in a variety of positions but generally between the oil pan and engine block or along the main bearing caps. Some fitting to your individual engine may be required and the procedure for carefully checking this is explained in the installation instructions.

Click on the text or image below to read more about installing Teflon® bladed scrapers

Do they really work?

Yes! The drysumped Merlin V12 aircraft motor from WWII had a rudimentary scraper directing oil to the scavenge pump. Crank scrapers in various forms have been in use in stock passenger car engines for about 100 years!*** More importantly, they are currently in use in a variety of OEM engines of both large and small displacement -- from relatively low RPM V8 engines to high RPM straight fours. Most auto enthusiasts are surprised to learn just how common they really are. In short, it is an extremely well-proven technology that is often simply not recognized. The modern trend is to have many more oil control devices in engines. Crank scraper technology is OEM equipment on various modern engines from Nissan, BMW, Chrysler, Ford, Mazda, Honda, Toyota, VW, Porsche, GM, Pontiac, Chevrolet, Mitsubishi, Mercedes and many other manufacturers.

[*** In 1923, Clair Smith applied for a patent for a device used in splash lubricated engines to reduce an overabundance of lubrication in some areas and redirect it to other areas receiving less lubrication. This design was a forerunner of the scrapers subsequently used in positive crankcase lubrication motors; patent 1,569,404.]

For example, here are a couple quotations from a recent patent held by General Motors; click here for more information about Mr. Tom Bishop:

| During operation of the engine, some oil that would otherwise drain into the oil pan may instead become entrained in crankshaft windage, which is air that rotates with the crankshaft. To address this situation, the engine may be provided with one or more oil scrapers that are attached to the main bearing caps with fasteners. ... In one embodiment of the invention, the baffle is adapted to scrape oil from crankshaft windage associated with the crankshaft. |

|||||||||||||

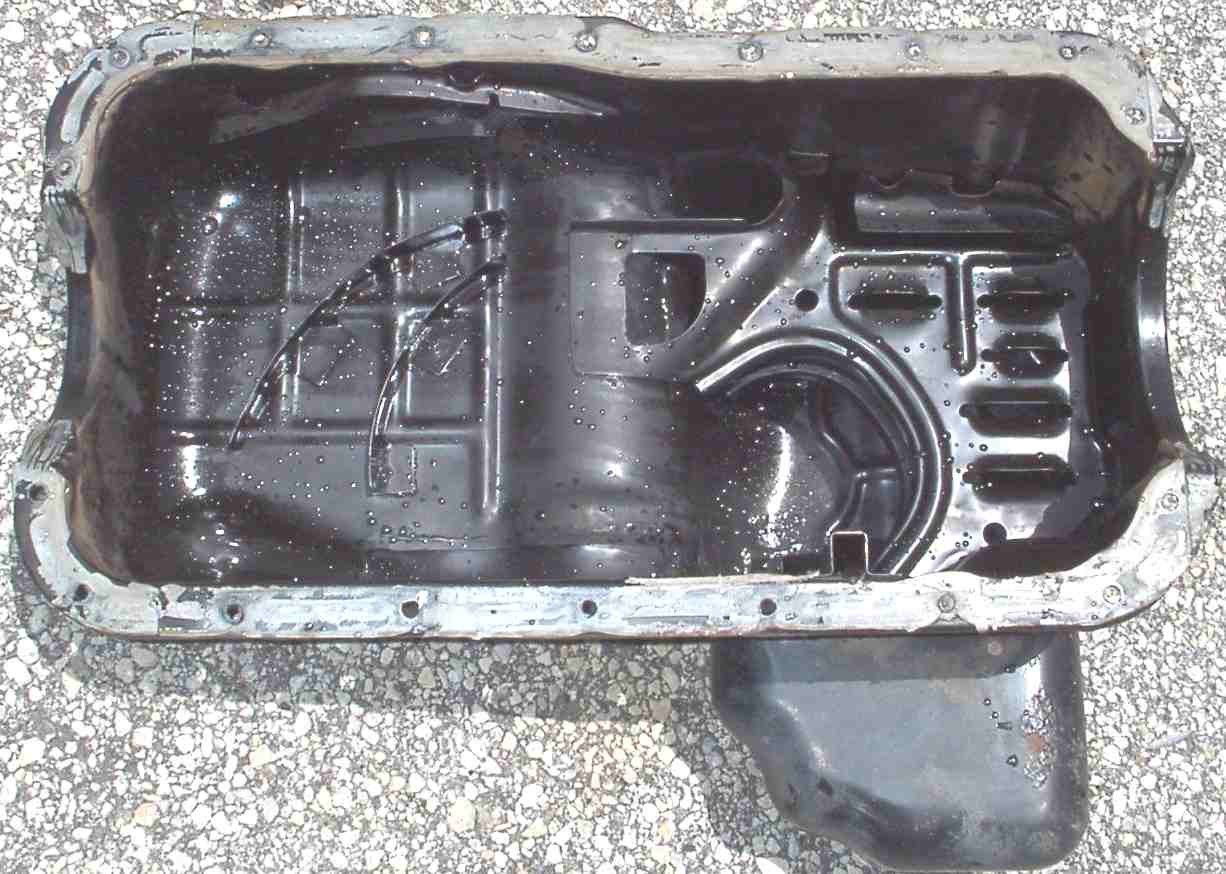

Oil pan with vertical baffles An oil pan for use with an engine having a crankshaft includes a pan body adapted to be disposed beneath the crankshaft for receiving oil that is exhausted from the engine. The oil pan further includes a vertically extending baffle attached to the pan body.

|

Some pictures of OEM crank scraper technology in passenger car motors...

|

Left: Here is a picture of a Dodge 2.7 windage tray with scraper louvers -- the louvers even have cutouts for the rod bolts.

The lower picture is of a Pontiac 389 from nearly 40 years prior. Notice the use of scraper louvers in the tray. |

||

| Right: Joe Donnelley sent us this picture of a scraper in the 1966 Oldsmobile Toronado oil pan. Thomas R. Leonard holds patent 3,354,988, which was assigned to General Motors.

As with the Pontiac 389 windage tray of the same vintage, the edge of the louver or scoop acts as a form of scraper. |

|

||

| Right: Mercedes diesel with multiple scrapers. These scrapers impart a vector or directed force towards the sump at the front of the pan. The same idea can be found in the earlier Ford 390 FE engine pan in a following photograph. |  |

||

|

|

|||

| Right: Ford 390 pan, crank scraper on the floor |  |

||

|

Left: Porsche 968 pan, multiple crank scrapers on floor | ||

| Right: Nissan VG30DETT; numerous scraper devices; patent 4986235. |  |

Is a windage tray the same as a crank scraper?

No, a windage tray serves a different but related basic function. It is present to act as a physical barrier between the rotating assembly and the sump reservoir. A crank scraper actively removes excess oil and returns it to the sump. Some windage trays do have scraper technology built into them but even then a dedicated scraper will approach the moving parts much more closely.

There are all sorts of industry terms for parts that function as a windage tray (often in addition to other functions) such as baffle, deflector and so on. Many times multiple levels of windage trays are used. This is because the design requirements for windage trays in an engine under acceleration are often diametrically opposed. Care must be taken that a windage tray does not become a de facto second sump by sealing the actual sump well area off too effectively.

|

|

|

Above: Honda B-series engine showing an installed Teflon® scraper on the left and the factory windage tray covering the entire assembly on the right. The windage tray shields the rotating assembly from splashing sump oil while the scraper actively removes excess oil. Before 6000 RPM the standard steel version of this scraper returned a 1.5 % to 2 % hp gain and from 6000-8900 RPM the hp gains averaged 2.5 %. Remember that this was on a statically mounted engine already having a full windage tray as with the Suzuki G10 mentioned below.

A windage cloud will still form on a statically mounted engine with a full windage tray. For example, roller dyno testing of a scraper in the Suzuki 993 cc three-cylinder G10 engine with a full windage tray still showed an average 3 % hp increase (over four pulls data ranged from 2.4 % to 3.5 %). Power began growing at about 2750 rpm and peaked at 5300 rpm (the maximum for that economy cam). Here are the dyno charts. In a moving car the oil would be sloshing around and making at least partial contact with the rotating assembly creating larger windage losses -- consequently the gains would be greater when using a scraper.

Will my engine still get enough internal splash lubrication?

Yes. The rod and main bearing journals are constantly spraying large amounts of oil in all directions when the engine is operating. Much of this oil lands directly on the cylinder walls and other internal components which depend on splash lubrication. The scraper removes oil directly only from portions of the surface of the crankshaft and the rod big ends, neither of which depend upon lubrication of any sort. These components, as well as the pistons, do depend upon a flow of oil to cool them. By constantly removing oil that has contacted these hot surfaces and allowing fresh oil to re-wet and cool them the thermal efficiency of the motor is enhanced. Hopefully, too, the user is reassured by over four decades of the successful and dependable use of scrapers in OEM stock engines as well as competition engines of all sorts.

Many enthusiasts remember splash lubricated engines where the big ends of the rods dipped directly into the sump reservoir for lubrication. This is essentially pre-WWII technology and does not apply to modern motors with positive pressure bearing lubrication from an oil pump.

Can the retroactive application of this technology help solve longstanding problems with certain engines?

Yes. In 2005 we designed a complex system of scrapers, windage trays and baffles that allowed the wetsumped Porsche 928 to survive a full season of high rpm racing without the well-known 2/6 rod bearing failure. This was unprecedented in the history of this engine.

General answers: What is windage and what are the differences between an oil baffle versus a windage tray versus a crank scraper?

Windage:

During normal engine operation a significant amount of oil becomes entrained in a cloud surrounding the spinning bottom end. As the oil droplets are atomized by the action of the spinning rotating assembly the smaller droplets are drawn into this cloud by the phenomenon known as the Tea Leaf Paradox, first described by Albert Einstein in 1926. This oil eats up horsepower your engine is making by increasing the rotating mass and also creating parasitic drag. Windage is actually a highly complex set of phenomena. Windage effects increase with: vehicle movement; rpm; stroke; blow-by (atmospheric pressure); bearing clearance; component surface characteristics, oil squirters (there are many types); draining oil from the head, cams, balance shafts and other internal components as well as oil returns from turbos, air-oil separators and catch can drains. Closely related topics are those of pumping losses, crank case ventilation, NVH (noise, vibration, harshness), oil aeration and the cooling function that is required of oil in addition to its lubrication tasks.

There are a number of different types and degrees of oil aeration starting from the baseline solubility of air in a given oil formulation at a given pressure and temperature (about 9% in a paraffinic base at saturation at one bar and 100 degrees C) and progressing through to actual foaming of the oil into a shaving cream like mix.**** Oil aeration can cause innumerable problems but some common ones are bearing failure, lifter collapse, oil pump failure and over heating and subsequent destruction of oils (and engines).

Baffles, windage trays and scrapers:

An oil baffle is a physical barrier to oil movement that is generally all or partially submerged in the wet sump oil reservoir. Sometimes small fins in other areas of the pan floor or engine can be seen that guide draining oil back to the main sump reservoir and these can be considered oil baffles as well. Typically these are seen in OEM cast aluminum sumps. Here is a picture of a Mercedes diesel motor sump with many baffles that are also crank scrapers. The idea is to keep the end of the pump pickup tube constantly submerged in oil so that it does not suck in air. Some baffles include trap doors that swing and close to enhance this function. So, baffles are ultimately intended to guide fluid consolidated oil to, and keep it around, the oil pump pickup.

A windage tray should prevent fluid reservoir oil that is sloshing from coming into direct physical contact with the rotating bottom end. Windage trays are also meant to shield the reservoir oil from the aerodynamic forces of the rotating assembly. These two basic functions often are in direct conflict with one-another with respect to decreasing the total effects of windage.

A crank scraper (sometimes known as an oil wiper, etc.) is a broad term for technology that actively strips away oil entrained in the air around, as well as oil physically adhering to, the rotating bottom end. Crank scrapers also serve to disrupt the pressure differential that forms in and around the rotating assembly.

Baffles, windage trays and crank scrapers all serve related functions and all can be of mixed design, i.e. dual or even triple purpose. Remember that different OEMs and cultures often use idiosyncratic terms for these various devices so this is only a general guide.

Some modern motors like the Ford Coyote introduce air flow near the central axis of rotation which at high rpms helps to reduce the pressure differential holding entrained oil droplets from within.

**** This video of raw data periodically shows how highly aerated oil drawn into an oil pump will emerge from cam bearings like shaving cream. http://www.youtube.com/watch?v=SmjQn3IBsP8

What about dry sumps: do they eliminate windage?

There are many levels of dry sump technology as well and windage is still an important issue in their design. Dry sumps are primarily intended to deliver an uninterrupted supply of quality oil to the bearings under all reasonable types of vehicle movement (aircraft systems are more complex). Oil aeration is reduced but not eliminated. The faster the engine spins the higher the quality of the oil supply needed and so in F1, for example, many more stages and/or scavenge points could be in use along with active versus passive oil deaerators. Mercedes engineers have remarked that up to 8% of the output of a passenger car motor can be lost to oil churning.***** Feedback from drag racers measuring ETs before and after oil control improvement suggest the percentage loss can easily exceed this.

***** See SAE 750051, page 5. http://papers.sae.org/750051/

Some videos of crank scraper installations:

|

Copyright 2002-2026 © All rights are reserved on our product designs -- a great deal of hard work goes into each one. Teflon® is a registered trade mark of E.I. du Pont de Nemours and Company. Only DuPont makes Teflon® resin sourced by Ishihara-Johnson Crank Scrapers from authorized DuPont licensees. We Ship

|